When and Why You Should Consider a 48V Motorized Drive Roller

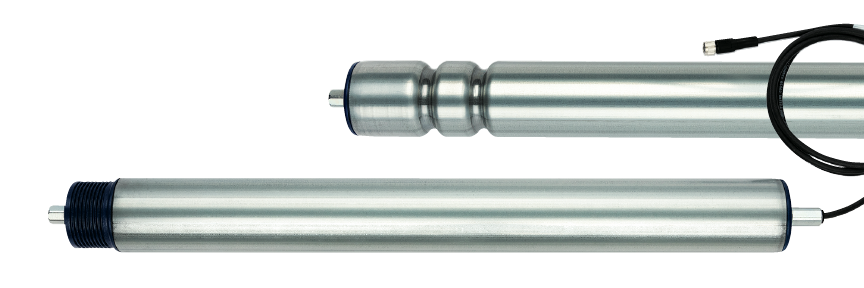

Choosing the right motorized drive roller (MDR) voltage has a significant impact on the performance and reliability of your conveyor system. While 24V MDRs have long been standard, the advantages offered by 48V technology can deliver notable improvements depending on your specific needs.

This article explains fundamental differences between 24V and 48V MDR solutions, highlights situations when 48V MDR is the optimal choice, and illustrates the practical benefits of upgrading.

Consistent Torque for Enhanced Acceleration

A key benefit of selecting a 48V MDR is the consistent torque it provides throughout the entire operating speed range. Unlike 24V motors, which may experience torque drops at higher speeds or during prolonged operations, 48V motors deliver steady and reliable torque. This advantage directly translates into quicker acceleration, smoother operation, and more predictable conveyor performance.

For applications such as pallet handling, sorting operations, or dense product accumulation zones, steady torque ensures conveyors maintain efficiency and throughput, even under heavy or fluctuating loads. With their linear acceleration characteristics, 48V MDRs respond promptly, providing reliable performance in automated systems.

Extended Cable Runs for Greater Flexibility

Another significant advantage of 48V MDR technology is its ability to accommodate longer power cable runs without experiencing voltage drops. Typically, 24V systems have reliable cable lengths limited to around 216 feet. In contrast, 48V systems extend this capability up to approximately 350 feet, depending on cable sizing and current demands.

Longer cable runs enhance flexibility in system design, reduce the complexity of electrical infrastructure, and simplify installation processes. Fewer power supplies may be required, which lowers costs and streamlines ongoing maintenance.

Reduced Power Supply Requirements

By utilizing 48V MDR solutions, facilities frequently reduce the number of power supply units necessary within the conveyor layout. Fewer power supplies not only lower upfront equipment costs but also reduce complexity, resulting in simpler electrical installations. A simplified system is easier to manage, maintain, and troubleshoot, ultimately enhancing overall reliability and decreasing downtime.

Broader Operating Range and Torque on Demand

An additional practical advantage of 48V MDRs is their wider operational range in terms of speed and torque. A broader range allows operators to effectively use one motor across multiple conveyor tasks, simplifying inventory and logistics while accommodating various load and speed requirements.

Furthermore, 48V motors deliver torque on demand, which means full torque is available whenever necessary—not just briefly during startup. This advantage ensures that conveyors can consistently handle heavier or unexpected loads, maintaining peak performance at all times.

Significant Increase in Power

The difference in available power between 24V and 48V MDRs is substantial. Typical 24V motors produce around 50 watts of power, whereas comparable 48V motors deliver between 80 and 100 watts. This near doubling of available power means 48V MDRs easily handle heavier loads, higher throughput demands, and intensive conveyor operations, resulting in improved productivity and efficiency.

Choosing Your MDR Solution

Determining whether a 48V MDR is the right choice for your operation requires a careful evaluation of your specific requirements. Facilities that handle heavier products, maintain extended conveyor runs, or require robust acceleration and advanced automation capabilities will especially benefit from switching to 48V technology. Reviewing your unique operational goals and needs will ensure the correct choice.

Pulseroller is ready to support your decision-making process with detailed guidance and specifications tailored specifically to your conveyor applications. To learn more about how our 48V MDR solutions can improve your system's performance, reach out directly to our team.