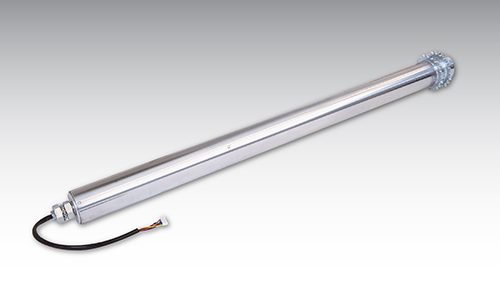

PULSEROLLER® Pallet Handling Motor Rollers Move Pallets up to 70" Wide While Reducing Energy Consumption

ERLANGER, KY (March 17, 2021) – PULSEROLLER pallet handling motorized drive rollers (MDR) safely and effortlessly move pallets up to 70" wide and weighing up to 2700 lbs. on a conveyor line. The low voltage pallet rollers are designed to replace any AC gear motor solution by simply removing the motor/gearbox unit and dropping in the heavy-duty pallet roller with sprockets directly inline with the other conveyor rollers. Depending on the application, energy savings can be as high as 60% compared to alternatives while providing a much safer and more energy-efficient conveying solution.

ERLANGER, KY (March 17, 2021) – PULSEROLLER pallet handling motorized drive rollers (MDR) safely and effortlessly move pallets up to 70" wide and weighing up to 2700 lbs. on a conveyor line. The low voltage pallet rollers are designed to replace any AC gear motor solution by simply removing the motor/gearbox unit and dropping in the heavy-duty pallet roller with sprockets directly inline with the other conveyor rollers. Depending on the application, energy savings can be as high as 60% compared to alternatives while providing a much safer and more energy-efficient conveying solution.

According to Mr. David Sellers, Director of Operations and Marketing at PULSEROLLER, "Building the perfect pallet conveyor just got easier...not to mention smarter, faster, safer, and more cost-efficient. Our pallet roller is driven by a powerful 24VDC motor engine installed inside the tube and coupled to an industrial hardened multi-stage planetary gearbox assembly that easily conveys loads of 2700 lbs. Conveying heavier loads is possible by adding another motor inside the tube, creating a dual-motor roller, or doubling the number of pallet motor rollers in each zone. We understand the importance of having options for conveying heavy-duty loads with low voltage pallet handling motorized drive rollers. In a time when others are shying away from the challenges of heavy-duty pallet rollers, PULSEROLLER is reinvesting, growing, and shining in this market."

Using PULSEROLLER's industry-standard ConveyLinx control card, PULSEROLLER pallet rollers can reach speeds up to 25 meters/minute with up to 49.3 N-m (436 in-lb.) of torque. This enables a user to move heavier loads with less energy (current) while maintaining the required speed.

With a choice of EthernetIP, Modbus TCP, ProfiNet, or EtherCat connectivity, the networked ConveyLinx cards facilitate virtually any control strategy at an affordable price. Simple ZPA, transportation, indexing loads, minimum pressure, sortation, pick & pass are all strategies easily implemented using the built-in intelligence of ConveyLinx or by writing a program directly. Users have complete control and monitoring capabilities of every motor in your system over a single Ethernet network.

PULSEROLLER pallet handling motor rollers are available in standard 2.25", 2 3/8", and 2.5" diameters with a plethora of optional attachments, including sprockets and poly-vee, keyway, timing pulley, and more.

About PULSEROLLER

PULSEROLLER is the brand name for a family of 24V DC motorized drive products and controls. The PULSEROLLER brand consists of a variety of motor drive rollers (MDR) of various diameters and configurations, geared drive motors, the most advanced ethernet networked drive controllers, and various other components required to assemble and implement motor driven roller conveyors and systems.

Globally known, PULSEROLLER products are available from a variety of resources around the world and are manufactured in North and South America, Europe, and Asia.