Power Distribution Cables

Power for the conveyor builder.

Power distribution wiring can be a hassle at times. You have to figure out the most affordable way to wire a 24V system while using the smallest amount of copper possible. Our power distribution methods have been put into the field time and time again by multiple manufacturers of conveyor with no issues at all.

.png)

- Specifically for use with our controllers

- Color coded connectors for error free instalation

- Insulation displacement tap kits to accommodate flexible controller mounting locations

.png)

- Plug and Play Convenience

- Economical

- Designed with the conveyor builder in mind

- Convenience

- Economical

- Specifically for use with our controllers

- Faster commissioning times

.png)

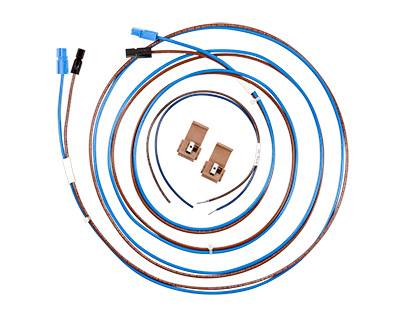

Power_Distribution_Harness

Power_Distribution_Harness

Part Number: PD-XXX

Description: 12 AWG Power Distribution Cable drawing in DWG format. Cables are premade to XXX cm length to easily snap one conveyor section to another in a plug and play fashion. Use with PTK-XX Power Tap Kits Power_Distribution_Harness

Power_Distribution_Harness

Part Number: PD-XXX

Description: 12 AWG Power Distribution Cable drawing in PDF format. Cables are premade to XXX cm length to easily snap one conveyor section to another in a plug and play fashion. Use with PTK-XX Power Tap Kits Power_Tap_Kit

Power_Tap_Kit

Part Number: PTK-XX

Description: Power Tap Kit drawing in DWG format. PTK-XX is used in conjunction with the Power Distribution harness in XX cm length. Splice the buss wherever a drop needs to be made for a Conveylinx, IQZonz, or EZ24 module. Power_Tap_Kit

Power_Tap_Kit

Part Number: PTK-XX

Description: Power Tap Kit drawing in PDF format. PTK-XX is used in conjunction with the Power Distribution harness in XX cm length. Splice the buss wherever a drop needs to be made for a Conveylinx, IQZonz, or EZ24 module.